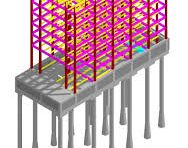

3D Layout of Components

3D design is the process by which designers create a 3D rendering of the proposed design.

Our design team produces all designs in 3D visuals. This enables our clients. To approve their displays and stands from every angle before production starts. Our solutions. Have helped many South African businesses to realize their vision and save money.

Our specialty also extends to providing graphic design and branding, retail kiosks and showcases.

3D Floor Plan

A 3D floor plan is a virtual model of a building floor plan. Depicted from a bird’s eye view. Utilized within the building industry to better convey architectural plans. Usually built to scale. A 3D floor plan must include walls and a floor. Includes exterior wall fenestrations, windows, and doorways. It does not include a ceiling so as not to obstruct the view. Other common attributes may be added. But are not required. Such as cabinets, flooring, bathroom fixtures, paint color, wall tile, and other interior finishes. Furniture may be added to assist in communicating proper home staging and interior design.

Structural elements of the wall

The steel reinforcements are drawn as a cylinder graphic elements. It is possible to observe. How to accommodate the steel reinforcements inside the structural elements. This is a real problem. Which is solved in the workplace. The steel elements are modeled based on the complexity of their allocation. It is then an illustrative example

3D City Models

A digital models of urban areas. It represents the terrain surfaces. The sites, buildings, and vegetation. Infrastructure and landscape elements. As well as related objects (e.g., city furniture) belonging to urban areas. Their components are represented by corresponding two-dimensional and three-dimensional spatial data. 3D city models support the presentation. Exploration, analysis, and management tasks in a large number of different application domains. 3D city models allow for integrating heterogeneous geoinformation within a single framework. And, create and manage complex urban information spaces.

3D Integrated Circuit

In microelectronics. A 3D integrated circuit is an integrated circuit manufactured by stacking silicon wafers or dies. Interconnecting them using, for instance, through-silicon vias or Cu-Cu connections. So that they behave as a single device. To achieve performance improvements at reduced power. Smaller footprint than conventional two-dimensional processes.

Model without detailed 3D components

3D integrated circuits are classified by their level of interconnect hierarchy. At the global (package), intermediate (bond pad) and local (transistor) level. 3D integration is a broad term.

Model with detailed 3D components

3D Chips

In 2004 Tezzaron Semiconductor built working 3D devices. From six different designs. The chips are built in two layers. With “via-first” tungsten TSVs for vertical interconnection. Two wafers are stacked face-to-face. And bonded with a copper process. The top wafer is thinned and the two-wafer stack was then diced into chips. The first chip tested. Was a simple memory register. But the most notable of the set was an 8051 processor/memory stack. That exhibited much higher speed and lower power consumption. t

The Intel chip was manufactured with two dies. Using face-to-face stacking, which allowed a dense via structure. For the 3D floorplan. Designers arranged functional blocks in each die aiming for power reduction. And performance improvement. Splitting large and high-power blocks and careful rearrangement allowed to limit thermal hotspots. The 3D design provides 15% performance improvement. A 15% power saving. This was due to the elimination of repeaters and reduced wiring.

Medical CAD/CAM>/strong>

3D scanners are used to capture the 3D shape of a patient in orthotics and dentistry. It supplants tedious plaster cast. CAD/CAM software is then used to design and manufacture the dental implants.

The Chair-Side dental systems use 3D Scanner. To capture the 3D surface of a dental preparation. To produce a restoration using CAD software. And produce the final restoration using a CAM technology.

Motor Vehicle<.strong>

An oblique view of a four-cylinder inline crankshaft with pistons

Many mechanical engineering companies. Especially those in industrialized nations. Have begun to incorporate computer-aided engineering programs. Into their existing design and analysis processes. This method has many benefits. Including easier and more exhaustive visualization of products. The ability to create virtual assemblies of parts. And the ease of use in designing mating interfaces and tolerances.